Navigating the world of certifications can be a daunting task, especially when it comes to ISO 3834—a standard focused on quality requirements for fusion welding. However, obtaining this certification doesn’t have to be an uphill battle. In this guide, we break down the steps to achieving ISO 3834 certification in a straightforward and approachable way.

Understanding ISO 3834 and Its Importance

ISO 3834 is an international standard specifically for ensuring the quality of welding processes. It is critical for manufacturers looking to improve product quality and safety, particularly in industries like construction, automotive, and aerospace.

The significance of ISO 3834 lies in its comprehensive approach to the welding process. It not only assesses the end products but scrutinizes every step of the welding operation to ensure quality consistency. This is crucial in mitigating risks associated with welding defects, which can lead to catastrophic failures, especially in critical sectors such as aerospace and construction. Moreover, the certification enhances customer trust by demonstrating a commitment to high-quality standards.

In essence, ISO 3834 serves as a benchmark for excellence in welding, providing a framework that helps organisations deliver superior quality products. With the growing demand for quality assurance globally, aligning with ISO 3834 not only streamlines operations but also opens up new business opportunities in markets that recognise and rely on certified partners.

Key Requirements for Certification

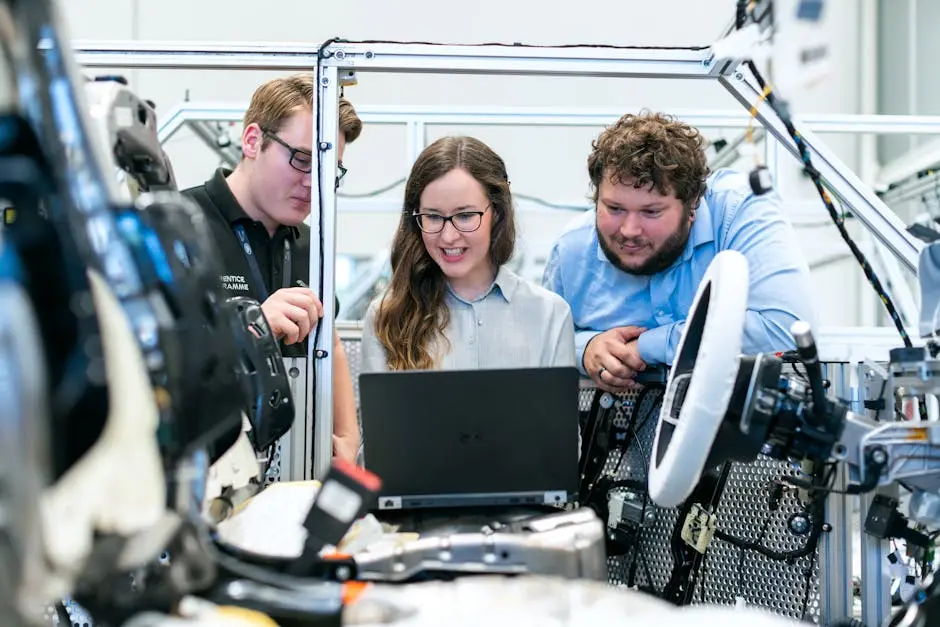

The certification process involves meeting specific criteria, including having qualified personnel, suitable equipment, and a robust quality management system. Each aspect is evaluated to ensure comprehensive quality assurance in welding operations.

Key elements of the ISO 3834 certification process include ensuring that all welding operations are performed under stringent quality controls. This involves having a documented system in place that encompasses qualified welders, welding procedures, and equipment calibration. Additionally, organisations must prove that they adhere to the specified requirements consistently across all operations, which often requires changes to existing processes and internal audits to confirm compliance.

Preparing Your Organization for ISO 3834

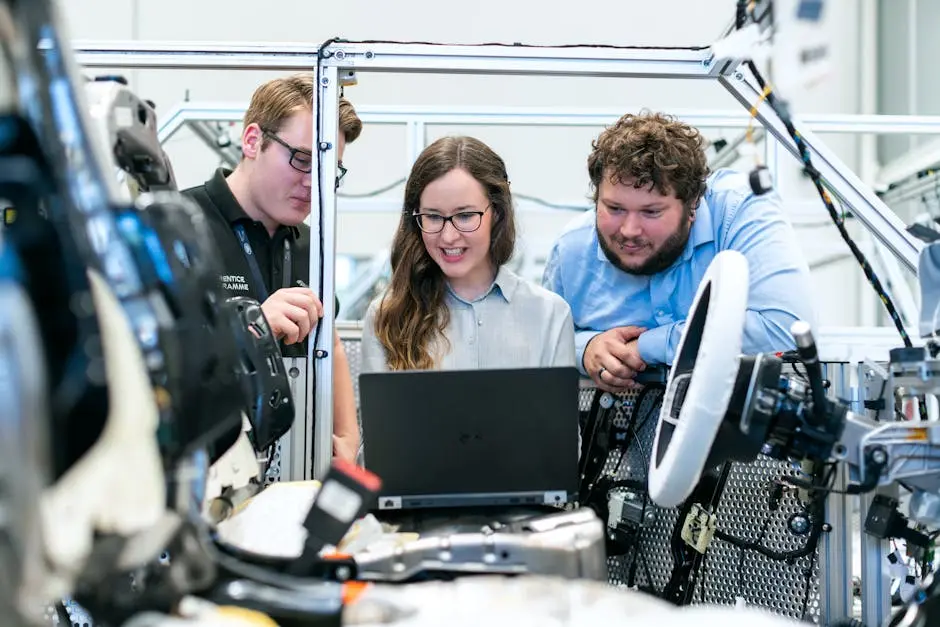

Preparation is crucial to a successful certification process. This involves assessing your current practices, training staff, and possibly making improvements in equipment and processes to meet the standards required.

A well-prepared organisation makes the certification process smoother. Start by conducting a gap analysis to identify how current practices compare with ISO 3834 standards. This analysis can highlight deficiencies and areas for improvement, prompting necessary changes in operational workflows and personnel training. It’s crucial that all staff understand their roles in maintaining quality standards, which often means investing in ongoing training and development.

Consider the technical aspects as well. Equipment should be up-to-date and in line with industry standards, and if calibration issues exist, they should be rectified immediately to avoid certification delays. It’s also wise to implement a comprehensive quality management system that oversees all operations, ensuring that any deviations are quickly identified and addressed. This proactive approach not only facilitates easier compliance but also instills a culture of quality and excellence within the organisation.

The Certification Process Step-by-Step

The journey to certification typically begins with a gap analysis, followed by implementation of necessary changes, applying for certification, and eventually undergoing an audit by an accredited body.

Initiating the certification process, organisations must first conduct a thorough self-assessment to establish their current position relative to the ISO 3834 requirements. This self-assessment often includes a detailed gap analysis to identify deviations and areas needing improvement. Subsequently, organisations embark on implementing the necessary adjustments to align their operations with the standard, focusing on areas such as process documentation, equipment adjustment, and personnel qualifications.

As these changes take hold, it’s time to apply for the actual certification. This involves submitting a formal application to a certified accreditation body, which is followed by an external audit. The audit process is rigorous and may include both document reviews and on-site evaluations to ensure that the standards are consistently applied and ingrained in the organisation’s operations. Clarity, preparedness, and transparency during the audit are key to a smooth and successful certification process. After passing the audit, the organization is granted ISO 3834 certification, a testament to its dedication to maintaining the highest quality in welding operations.

Maintaining Certification and Continuous Improvement

Once certified, it is important to maintain the standards through regular audits and updates to procedures, ensuring continuous compliance and improvement in welding quality.

Obtaining certification is just the beginning. To maintain ISO 3834 certification, organizations must commit to ongoing checks and balances, ensuring that the quality standards are upheld over time. Regular internal audits are essential for checking compliance, identifying potential issues, and implementing corrective actions promptly. These audits ensure that any quality lapses are addressed efficiently, keeping the organisation on track with its quality objectives.

Continuous improvement is at the heart of ISO 3834. Beyond audits, fostering a culture that encourages feedback and innovation in processes can lead to enhancements in efficiency and quality. This might involve embracing new technologies or adapting to market evolutions that demand higher standards or different methods. By prioritising continuous improvement, organizations not only reinforce their commitment to quality but also enhance their competitive edge in the global marketplace, setting a standard of excellence in welding operations.

Simplifying Your Path to Certification

Achieving ISO 3834 certification is a significant accomplishment that not only boosts your company’s credibility but also ensures high standards of welding quality. By understanding the process and taking each step at your own pace, certification becomes an attainable goal. Remember, it’s all about continuous improvement and commitment to quality.