We're Here To

Help

ISO 3834 is the internationally recognised standard for quality requirements in fusion welding of metallic materials. Achieving ISO 3834 certification demonstrates your business’s commitment to welding quality, safety, and compliance – trusted by clients, contractors, and regulators across construction, engineering, and manufacturing sectors. With ISO 3834, you ensure your welding operations meet strict technical and quality benchmarks, reduce the risk of defects, and strengthen your reputation for excellence. Compliancy Group guides you through every step – making ISO 3834 compliance clear, efficient, and a real business advantage.

We understand the specific challenges of welding quality assurance and ISO certification. Our team brings hands-on experience with welding management systems, technical requirements, and sector-specific compliance demands.

No one-size-fits-all here. Whether you need gap analysis, welding procedure qualification, ISO certification, or day-to-day compliance advice, our services are fully customised to your operations. We offer flexible support packages—from essential guidance to comprehensive on-site consultancy.

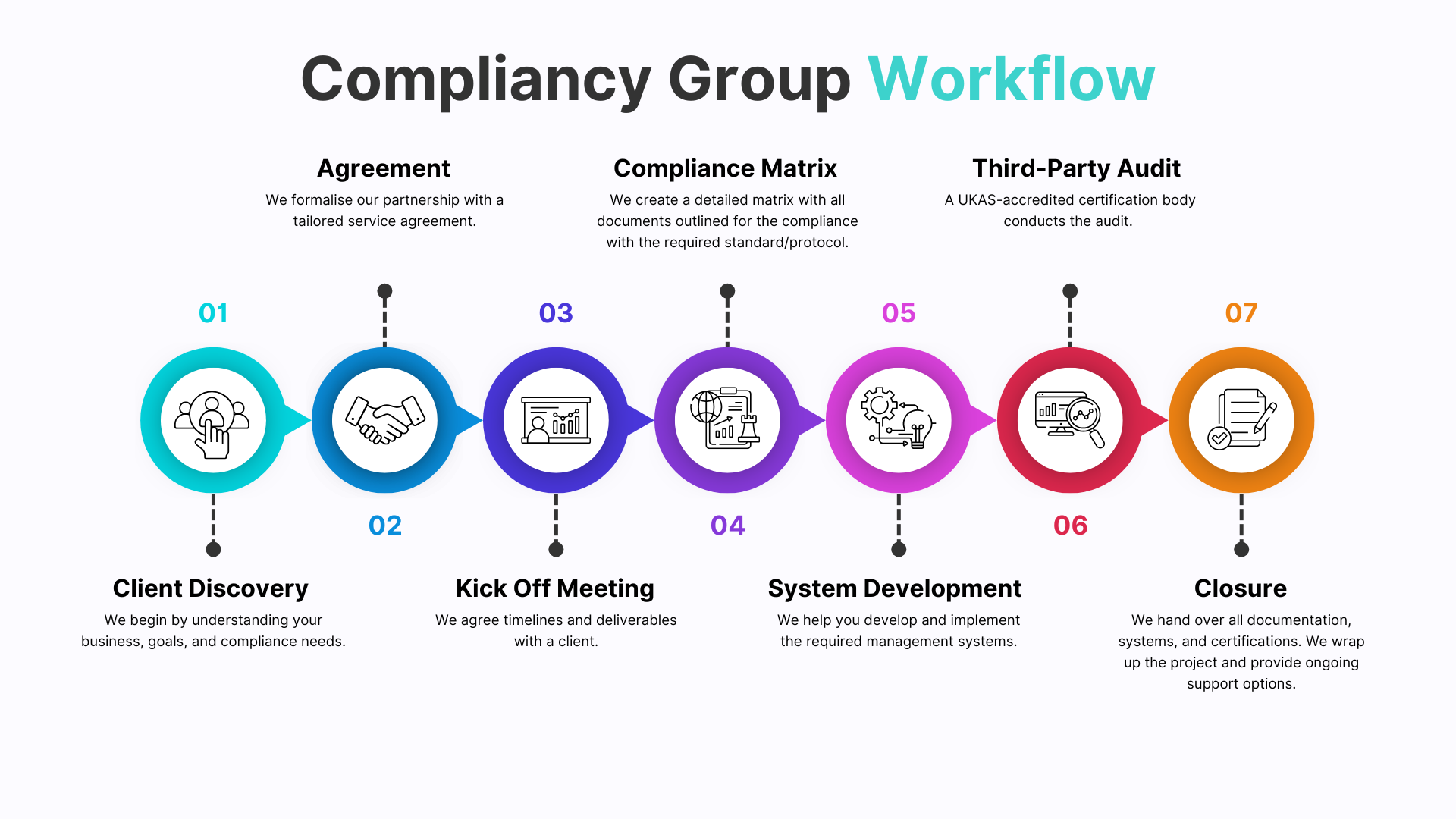

We work exclusively with UKAS-accredited certification bodies and maintain a 100% pass rate for certification assessments. Our clients trust us to deliver results that stand up to audit and regulatory scrutiny—helping you achieve, maintain, and leverage ISO 3834 compliance for business growth.

Compliance shouldn’t slow you down. We help you build safer, more resilient welding operations, reduce risk, and improve efficiency—so you can focus on delivering top-quality work and winning contracts.

You’ll work directly with our expert team, including leadership involvement from our CEO. We pride ourselves on responsive communication, clear guidance, and ongoing support throughout your compliance journey.

ISO 3834 certification opens doors to major engineering, construction, and manufacturing projects.

Demonstrate your technical competence and commitment to welding quality.

Meet strict quality requirements to minimise welding failures and costly rework.

Achieving and maintaining ISO 3834 sets you apart in the welding and fabrication sector.

Regular audits and compliance checks foster a culture of ongoing improvement and operational excellence.

Strengthen Reputation

From gap analysis to audit support, our team ensures you’re always prepared and confident.

We streamline compliance processes, freeing up your team to focus on core business activities.

Services are tailored to your specific business needs, not generic templates.

Ongoing support, training, and regulatory updates keep your business compliant long after certification.

Our 100% certification pass rate and exclusive partnerships with UKAS-accredited bodies mean you’re in safe hands.

The ISO 3834 defines three levels of welding quality: Comprehensive, standard and elementary. Our experts offer advice on which level is most suitable for your company and carefully guide you through the whole certification process.

ISO 3834 describes the requirements for a welding and fabrication control system aimed specifically at fabricators. Compliance with it is a mandatory requirement in a number of standards and specifications, e.g., BS EN 1090-2 and the National Structural Steelwork Specification.

ISO 3834 is a standard to guide manufacturers in the management of welding fabrication activities from design to delivery. Conformance to ISO 3834 can ensure manufacturing capability and staff competence, and it leads to a smoother and more sustainable fabrication.

Based on quality requirements, ISO 3834 is divided into three levels: ISO 3834-2:2005 (comprehensive quality requirements for welding). ISO 3834-3:2005 (standard quality requirements for welding).

EN-15085 is a specific standard for welded rail products. ISO-3834 is a general standard for welding quality control, which can be used in various sectors; construction, naval, medical, food... would be the basis of the system.

Background and Scopes of Application ISO 3834 specifies quality requirements suitable for fusion welding processes of metallic materials. It may be used in a variety of situations and for different applications, such as railway vehicles, steel structure, pressure equipment, and etc.

International Organization for Standardization (ISO) certification establishes credibility and trust among consumers, clients and other business partners. In today's international marketplace, such a designation validates that an organization adheres to global standards of quality assurance, manufacturing and business.

ISO 3834 describes the requirements for a welding and fabrication control system aimed specifically at fabricators. Compliance with it is a mandatory requirement in a number of standards and specifications, e.g., BS EN 1090-2 and the National Structural Steelwork Specification.